The LAUNCH X431 truck diagnostic tool performs the cutout cylinder function on a 2019 Foton Pilot truck.

Background information on the function:

When an engine experiences problems such as unstable idling, insufficient power, vibration, black smoke, or abnormal noise, it is impossible to directly determine which cylinder is malfunctioning based on visual inspection.

The Cutout Cylinder Test can effectively narrow down the scope of the fault and determine which specific cylinder is malfunctioning.

Cutout Cylinder Test: When the fuel supply (diesel engine) or ignition (gasoline engine) is cut off, the engine will show significant changes such as reduced speed and increased vibration due to a noticeable drop in power. This is normal.

If the engine’s operation remains almost unchanged after cutting off a particular cylinder, it indicates that the cylinder itself is either not working or is working very poorly, and is the source of the fault.

For modern electronically controlled high-pressure common rail diesel or gasoline engines, directly disconnecting the fuel line or ignition wire may trigger protection mechanisms or cause the engine to stall. In such cases, it is recommended to use the LAUNCH X431 diagnostic tool to cut off the injector operation via software commands, achieving a safer and more accurate diagnosis.

Tools used: LAUNCH X431 V+(PRO3) HD

(This can be done using other X431 PRO3 series and X431 PAD series tools that support truck diagnostics).

Test vehicle: 2019 Foton Pilot

Operation Procedure:

1) Connect the X431 diagnostic tool to the vehicle’s OBD port. In the X431 diagnostic software, click [Local Diagnose] -> [Foton].

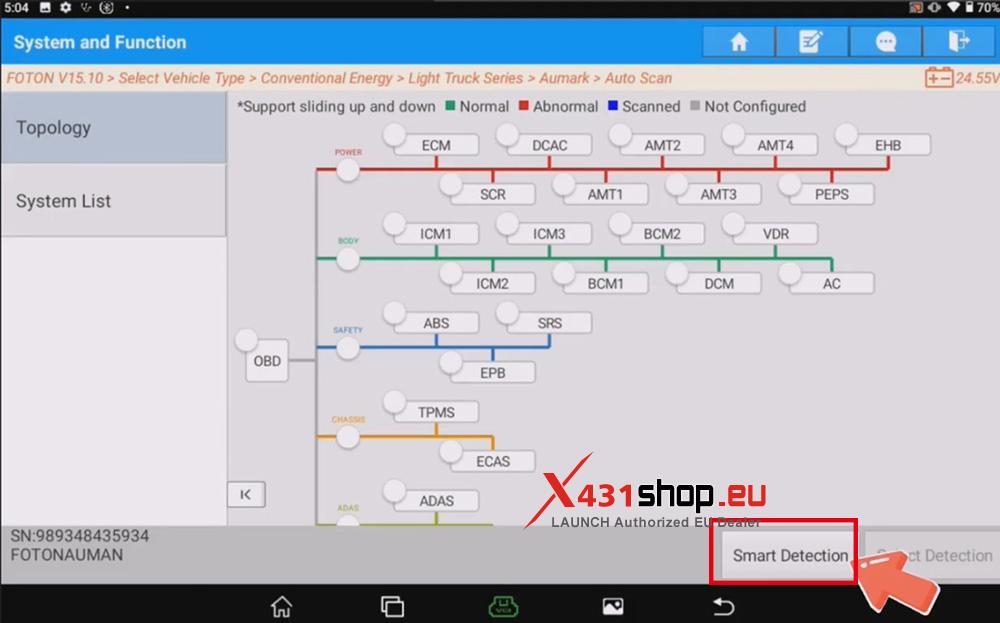

2) Click the function paths in sequence: [Select Vehicle Type] -> [Conventional Energy] -> [Light Truck Series] -> [Aumark] -> [Auto Scan].

3) On the topology page, click [Smart Detection].

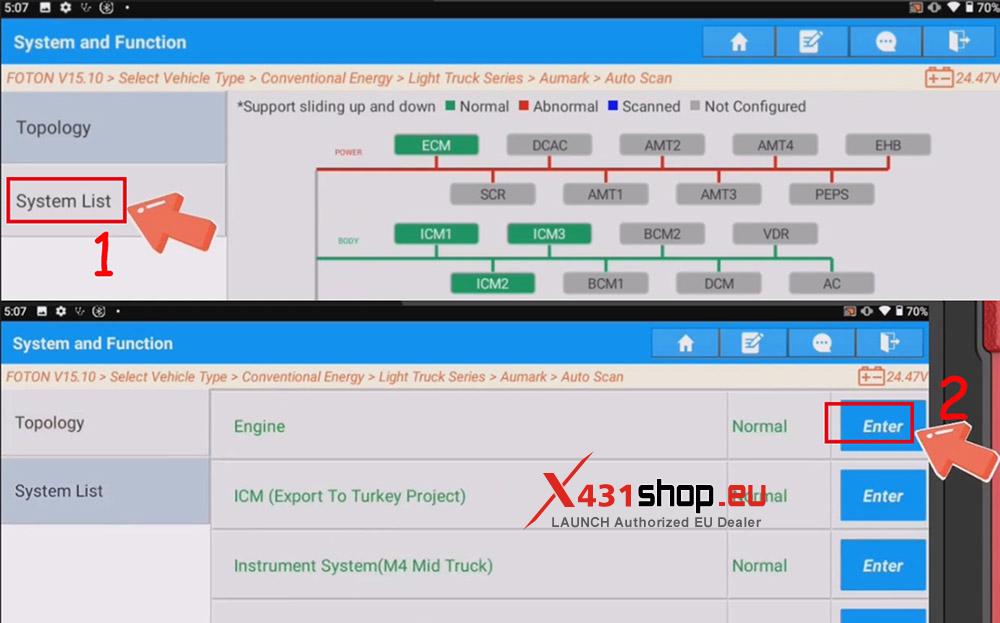

4) After the intelligent detection is complete, select [System List], and then click [Enter] in the Engine module.

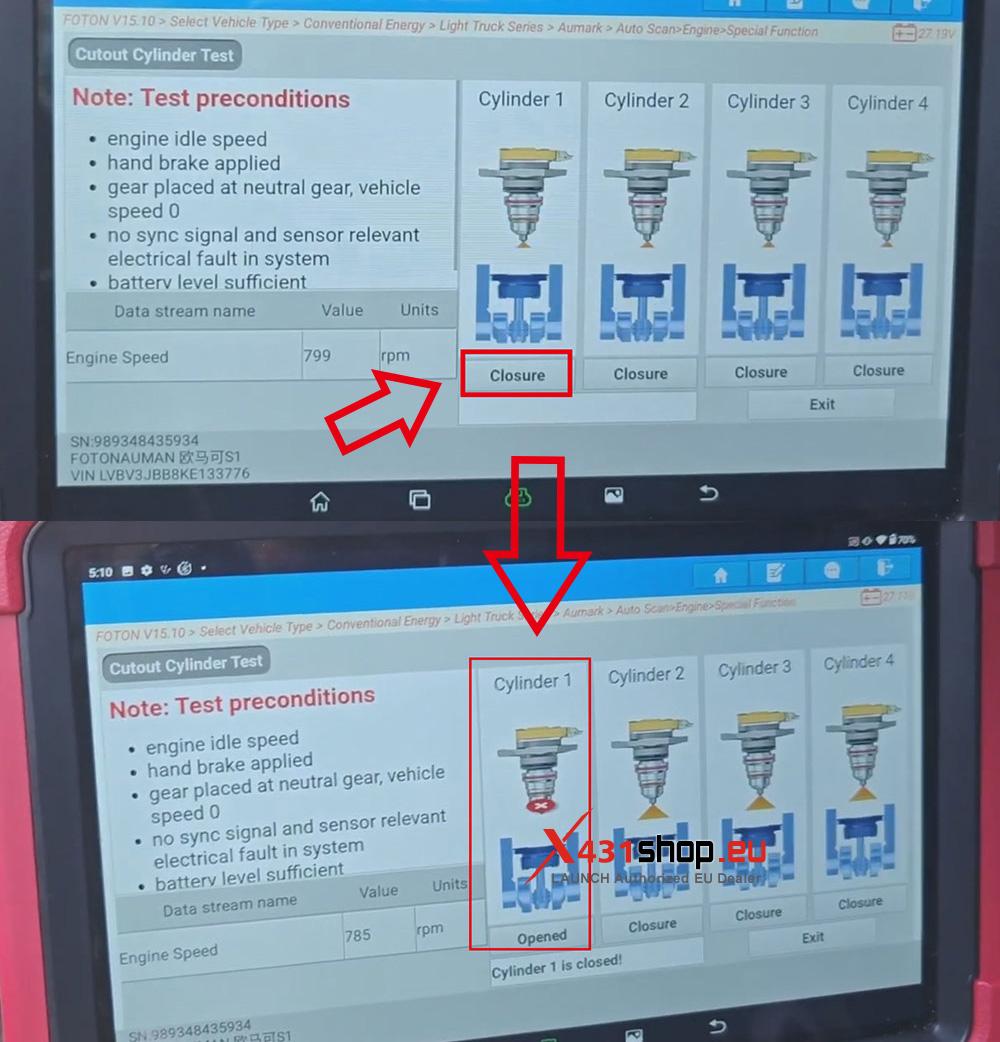

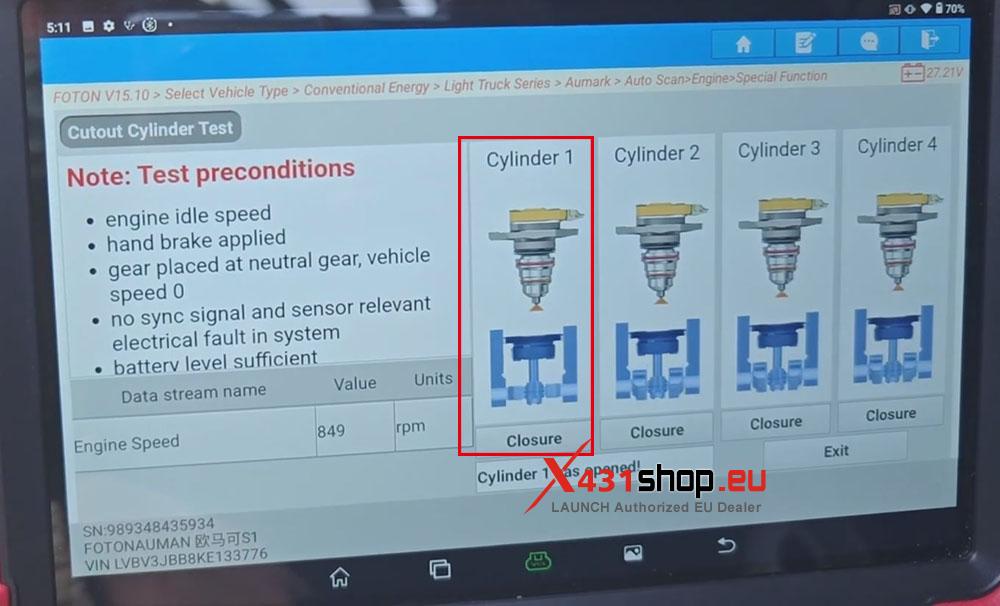

5) Click [Special Function] -> [Cutout Cylinder Test]. Read the information and click [Continue].

Test preconditions:

engine idle speed;

hand brake applied;

gear placed at neutral gear, vehicle speed 0;

no sync signal and sensor relevant electrical fault in system;

battery level sufficient.

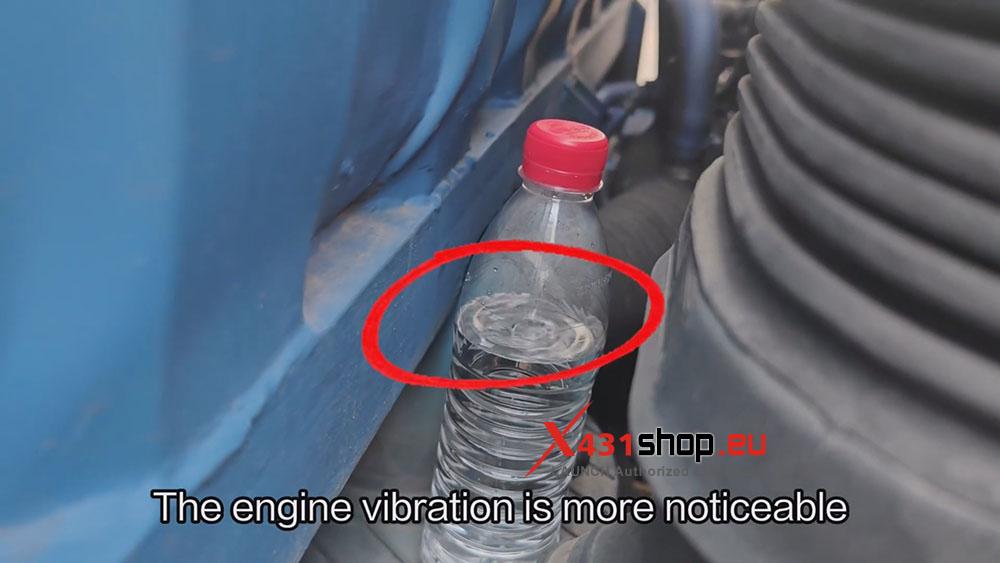

6) Click the [Closure] button on one of the cylinders and observe the engine status. If the engine vibration becomes more pronounced, the cylinder is working normally; if there is no significant change, the cylinder is faulty. (You can place a bottle of water on the car body and observe the vibration of the water surface.)

7) If the cylinder is found to be working normally after testing, be sure to restart the cylinder using the X431 tool. Prolonged cylinder deactivation testing may damage components such as the catalytic converter.

This concludes the introduction to cylinder deactivation testing.

Video reference: